Automatic Liquid Horizontal Premade Stand Up Pouch Doypack Packing Machine

- One Year Warranty

- User Manual

- One-to-one Video Chat Support

- Install & Debug Video

- Custom Package Solution

Automatic Liquid Horizontal Premade Stand Up Pouch Doypack Packing Machine

The Application of Automatic Liquid Horizontal Premade Stand Up Pouch Doypack Packing Machine

This liquid filling packing machine consists of the liquid pump and the host packing machine. It is suitable for various kinds of liquid products and can pack different premade bags. It is applied to various kinds of liquids such as honey, milk, oil, ketchup, paste, sauce, fruit juice, hand wash, laundry liquid, etc. After replacing the metering device, can also be used for packaging granular and powder products.

The Feature of Automatic Liquid Horizontal Premade Stand Up Pouch Doypack Packing Machine

1. Different machine models available to meet a wide range of premade bag sizes;

2. Customized main machine structure for various kinds of bag shapes. Like doypack zipper bag, 3/ 4 side seal bag, spout pouch, stand up bag and irregular bag, etc;

3. With upgraded PLC control system, easy to operate on touchscreen for parameter setting;

4. Machine can be equipped with different metering systems like weigher, liquid pump, auger filler, bucket chain for different kinds of product filling and packing in premade bags;

| Type | LDSP-160 | LDSP-160Y | LDSP-210 | LDSP-260 |

| Bag Type | 3-side, 4 side sealing bag, stand-up bag, handbag, spout bags, zipper bag, compound bag, etc. | |||

| Bag Size | 110-230mm*80-160mm(L*W) | 70-100mm*110-230(L*W) | 100-210mm/110-320mm(L*W) | 100-260mm/110-320mm(L*W) |

| Filling Range | 10g-100g | 10g-100g | 10g-1kg | 10g-3kg |

| Packing Speed | 20-45bags/min(speed is determined by the product filling quantity) |

25-50bags/min(speed is determined by the product filling quantity) |

20-50bags/min (speed is determined by the product filling quantity) |

20-50bags/min (speed is determined by the product filling quantity) |

| Machine weight | 800KG | 800KG | 900KG | 1000KG |

| Total Power | 2.0KW | 2.0KW | 2.0KW | 2.0KW |

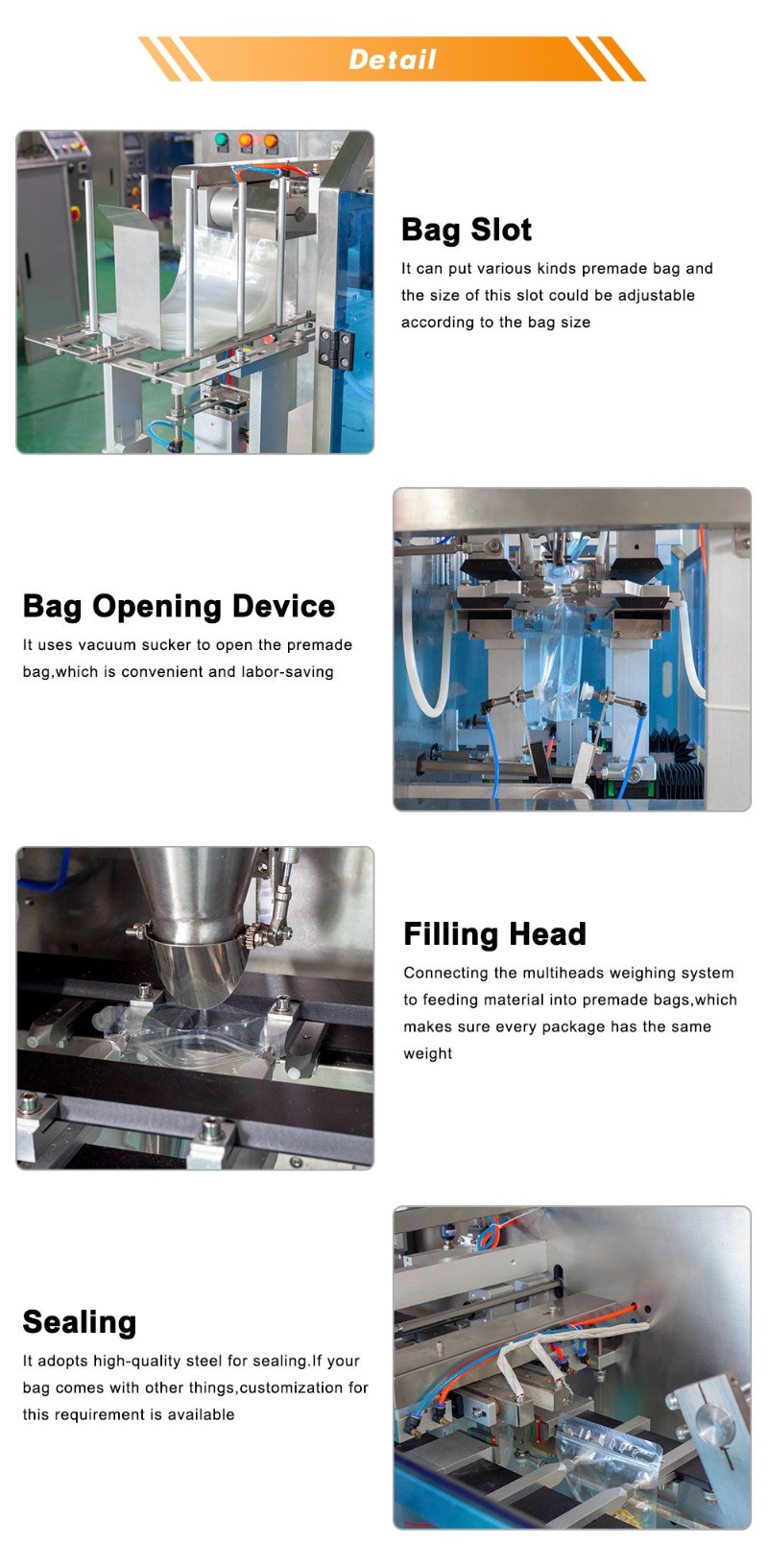

| Work Flow | 1. Giving bag, 2. Pick up the bag(coding), 3 .Open the bag up and down, 4. Filling, 5. Heating sealing, 6. Output of the product | |||

| Dimensions | 1750*1285*1360mm(L*W*H) | 2140*1366*1360mm(L*W*H) | 2140*1366*1360mm(L*W*H) | |

| Collocation | Screw metering, screw elevator | |||

The Work Process of Automatic Liquid Horizontal Premade Pouch Doypack Packing Machine

1. Picking up pouches

2. Receiving pouches and coding - (optional)

3. Filling product

4. Filling product

5. Sealing pouches

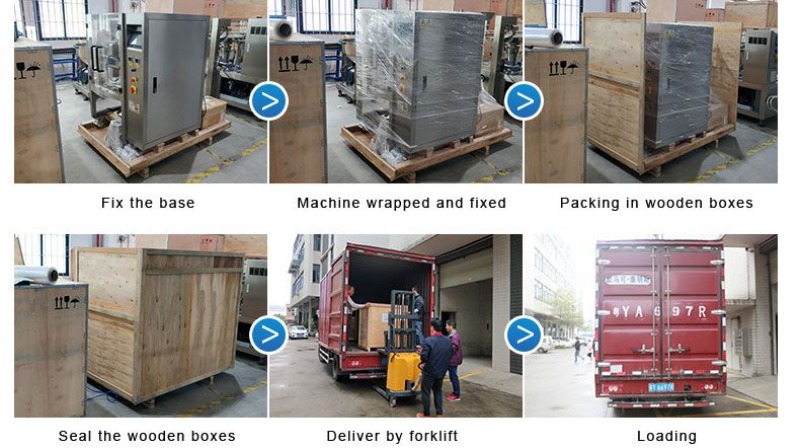

Packing & Delivery

1. We use the wooden case to pack our packing machine

2. Upon receipt of payment , delivery date will be in 10-35days, By Air, by Sea or by Express (DHL etc) Shipment cost will depend on the destination, shipment way and the weight of the goods.

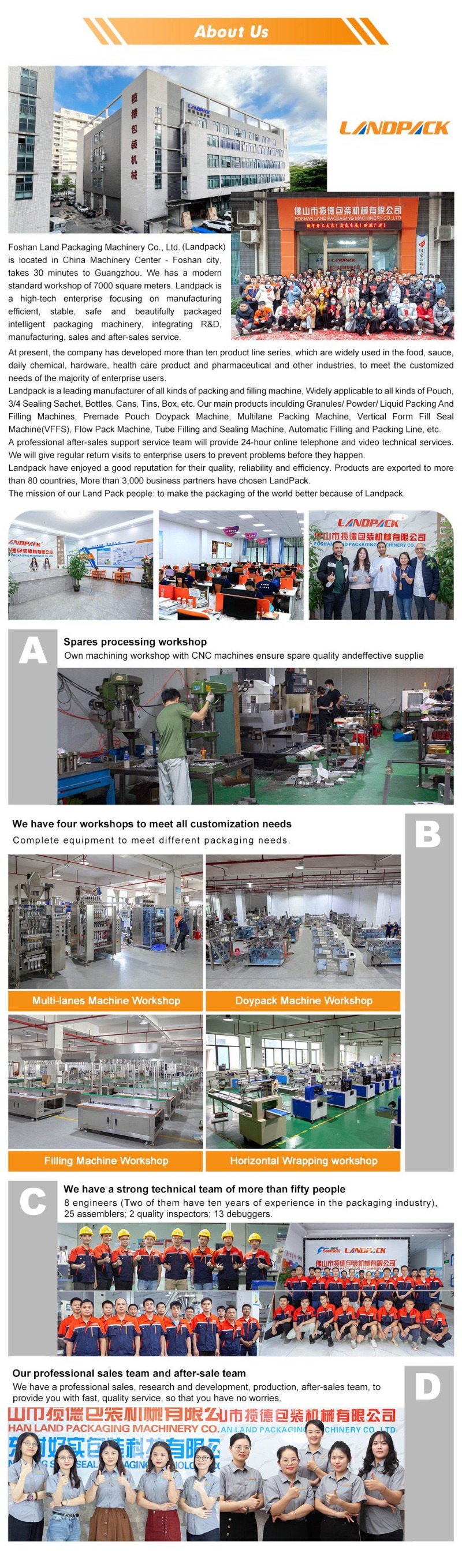

Company Profile

Our Organization

The manufacturing plant and facilities, designed with modern criteria complying with CE directives, and the advanced process technology based on an economy of scale production, place LANDPACK among China producers for the top quality of products as well as for the quantity and variety of solutions proposed and sold. Research and Development Department is equipped with advanced tools and has a qualified team of informatics, electronics and packaging experts involved in the study and experimentation of new solutions, indispensable for new projects and for the improvement of standard equipment.

Our Mission

Our aim is the complete customer's satisfaction, through research and trials of new automated packaging systems and technical solutions.

Our Objective

Designing and building automatic packaging machines technologically advanced, durable and reliable, interfaced with modular composed automatic feeders, easy to be integrated into automated packaging systems.

Our Sales and Service Network

Entrusted to Certified Agents of proven professional competence and expertise, employing Record trained service engineers, stocking a suitable inventory of original spare parts for immediate delivery.

FAQ

Q: What are your Installation Services?

A: Installation Services are available with all new machine purchases. We will provide the user manual and videos to support for installation, debugging, and operation of the machine, which will indicate to you how to use this machine well.

Q: What about your Guarantee of quality?

A: The machine is 1 year warranty, all machine parts can be replaced for free within 1 year if broken(not including man-made). And offer lifetime after-sales service

Q: How about the after-sales service?

A: (1)More than 12 hours of after-sales online service one day. (2) We have engineers available to service machinery overseas. The service charge includes: service fee USD100/day, VISA fee, round-trip ticket, room and eat on are buyer's side.

Q: How about the spare parts?

A: After we deal with all the things, we will offer you a spare parts list for your reference.

Q: If we have very special request for the production line, could you help me to do the design?

A: Experienced mechanical designer, customized design provided.

Q: If we have samples of new products, can you help to analysis and design the machine?

A: Yes, our technical department can help to analysis, design and test the new products you offered.

Q: Can I visit your factory?

A: Sure, our factory address: Plant 6-11, Floor 1, Building C7 of New Lighting Source Industrial Base, Langsha, Luocun, Shishan Town, Nanhai District, Foshan, Guangdong, China