High-Precision Pharma Tablet Pill Counting Filling Capping Labeling Machine Line

- One Year Warranty

- User Manual

- One-to-one Video Chat Support

- Install & Debug Video

- Custom Package Solution

High-Precision Pharma Tablet Pill Counting Filling Capping Labeling Machine Line

The Application of High-Precision Pharma Tablet Pill Counting Filling Capping Labeling Machine Line:

1. Pharmaceutical Industry: High-speed, accurate filling of tablets, capsules, softgels, lozenges, vitamins, and nutraceuticals into plastic or glass bottles.

2. Dietary Supplements & Health Products: Ideal for packaging gummy vitamins, herbal capsules, and health supplements with consistent counting and labeling standards.

3. Food & Confectionery: Can adapt to packaging candy, gummies, chewable tablets, and other small edible items requiring regulated filling.

4. Cosmetics & Specialty Products: Suitable for small cosmetic beads, pellets, or solid-form additives in bottles, with hygienic and dust-free processing.

5. Contract Packaging (CDMO/CDPO): Flexible for frequent product changeovers, various container types, and client-specific format adjustments.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

The Packaging Samples of High-Precision Pharma Tablet Pill Counting Filling Capping Labeling Machine Line

The Specification of High-Precision Pharma Tablet Pill Counting Filling Capping Labeling Machine Line:

| Model | Application | Capacity | Power | Gas consumption | Overall Dimension |

|---|---|---|---|---|---|

| 8 channel counting line | Tablets and pills below φ20 Capsule No.000–5 (customizable channels) | 20–40 bottles/min | 220V / 6.75 KW | 1.0 m³/min | 10000×850×2500 mm |

| 16 channel counting line | 50–80 bottles/min | 220V / 0.75 KW | 1.2 m³/min | 11500×850×2500 mm | |

| 32 channel counting line | 100+ bottles/min | 220V / 8 KW | 1.4 m³/min | 12500×850×2500 mm |

The Features of High-Precision Pharma Tablet Pill Counting Filling Capping Labeling Machine Line:

1. Multi‑Channel Electronic Counting System: 8–32 lanes with precision accuracy ≥ 99.8%, supporting outputs of 20–100+ bottles/min depending on channel configuration;

2.Stainless‑Steel GMP Construction: Machine frame built with SUS‑304; all product‑contact components in SUS‑316, fully compliant with GMP, CE, FDA standards;

3. Modular & Compact Design: Independent modules (unscrambler, counter, filler, sealer, capper, labeler), enabling rapid format changeover, easy separation for maintenance, and scalable upgrades;

4. PLC + Touch‑Screen HMI Control: User-friendly interface with recipe storage, parameter adjustment, fault alerts, and automated counting records;

5. Automatic Safety Interlocks: “No‑bottle, no‑fill” and “no‑cap, no‑fill” functions prevent product loss and ensure operator safety;

6.Integrated Sealing & Labeling Options: Optional desiccant inserter, cotton filler, foil/induction sealing, and high-speed labeling capabilities. Energy‑saving servo-driven capper;

7. Dust-Controlled & Hygienic Operation: Fully enclosed design with easy clean-in-place (CIP), minimal dust emission, and smooth surface finishes for sanitation;

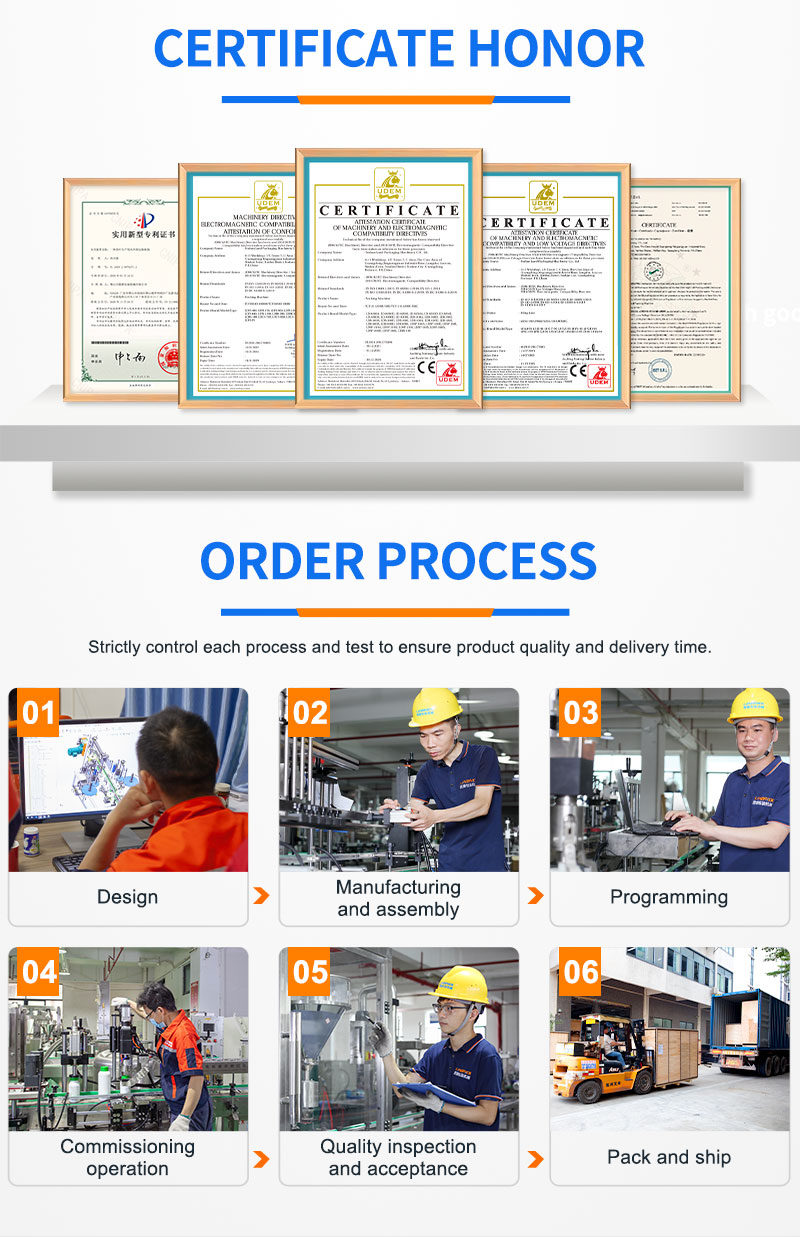

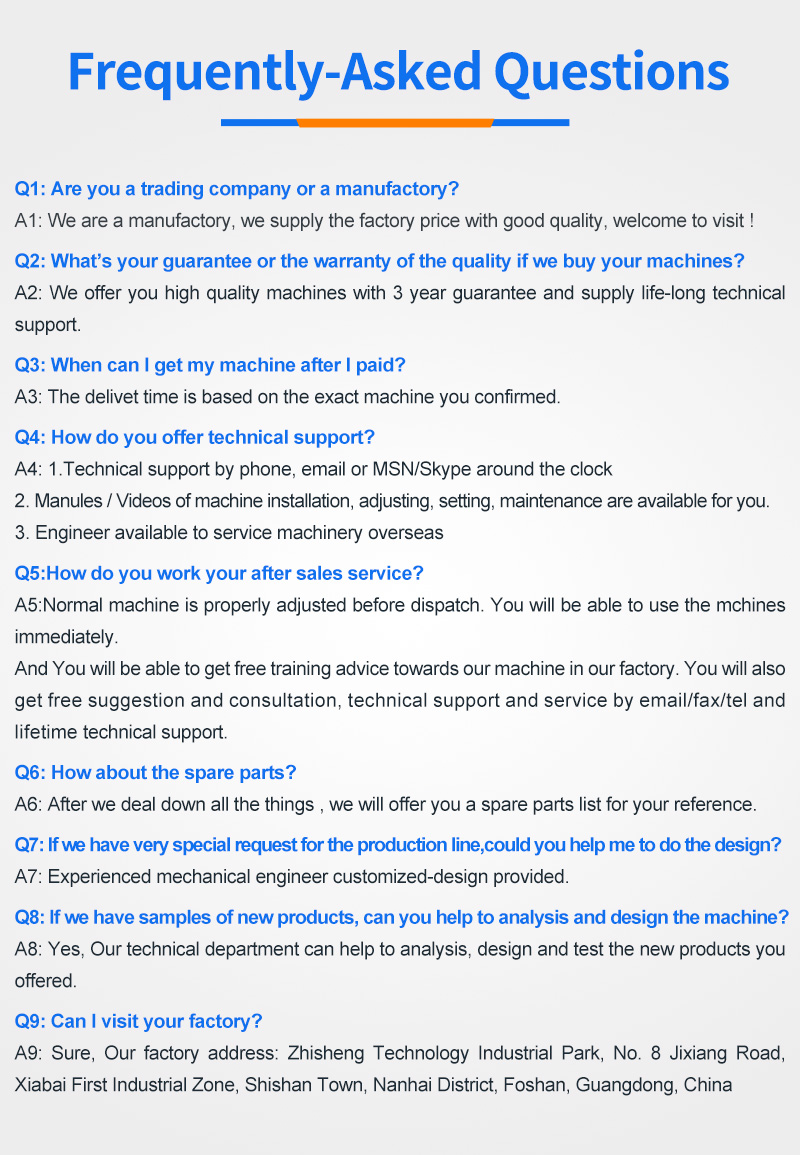

8. Global Support & Warranty: 3‑year warranty, 24/7 online support, worldwide engineer dispatch, and customizable configurations;