Automatic Dishwashing Powder Premade Pouch Bottle Filling Line System

- One Year Warranty

- User Manual

- One-to-one Video Chat Support

- Install & Debug Video

- Custom Package Solution

Automatic Dishwashing Powder Premade Pouch Bottle Filling Line System

Application Of Automatic Dishwashing Powder Premade Pouch Bottle Filling Line System

Automatic Dishwashing Powder Premade Pouch Bottle Filling Line System(LD-PAF01). It is suitable for automatic weighing filling capping and labeling of various fluidic or low-fluidity powder materials like washing powder, nutrition powder, chicken powder, milk powder, coffee powder, granular additives, etc. It's widely used in the various industry including foodstuff, cosmetics and chemicals.

(We have several models. We can customize the suitable one for you according to your requirements. Just Tell us: Weight or Bag.)

The Sample Of Automatic Dishwashing Powder Premade Pouch Bottle Filling Line System

The Feature Of Automatic Particle Sugar Salt Washing Dishwashing Powder Bottle Filling Line System

- Automatic feeding, weighing, filling, feeding spoon, collecting, save labor cost, improve efficiency.

- It can adjust different type bags and different weight.

- Stable working and simple operation.

Washing Powder Premade Pouch Doypack Machine Work Flow:

- Z type elevator

- Automatic feeding bags

- Zipper opening device

- 4 heads weigher for weighing and filling automatically

- Automatic feeding spoon

- Finished bag conveyor

- Finished bag collection table

1. Automatic feeding empty bottle.

2. 4 heads weigher for weighing and filling automatically.

3. Automatic feeding spoon.

4. Automatic feeding caps and automatic capping machine.

5. Finished cans collection.

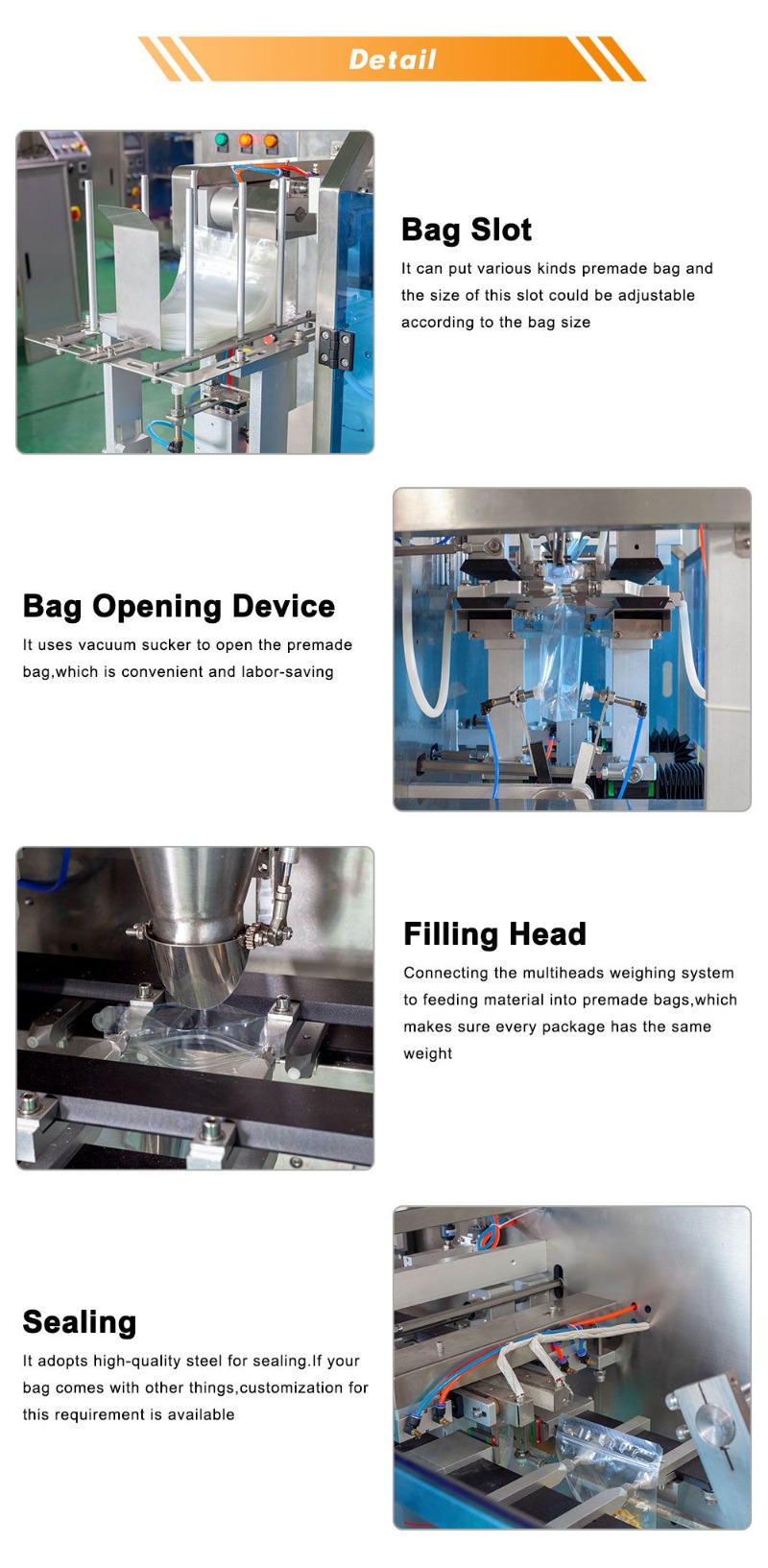

The Description Of Automatic Dishwashing Powder Premade Pouch Bottle Filling Line System

| Type | LDSP-160 | LDSP-160Y | LDSP-210 | LDSP-260 |

| Bag Type | 3-side, 4 side sealing bag, stand-up bag, handbag, spout bags, zipper bag, compound bag, etc. | |||

| Bag Size | 110-230mm × 80-160mm (L×W) | 70-100mm × 110-230mm (L×W) | 100-210mm × 110-320mm (L×W) | 100-260mm × 110-320mm (L×W) |

| Filling Range | 10g-100g | 10g-100g | 10g-1kg | 10g-3kg |

| Packing Speed | 20-45 bags/min (speed depends on product filling quantity) |

25-50 bags/min (speed depends on product filling quantity) |

20-50 bags/min (speed depends on product filling quantity) |

20-50 bags/min (speed depends on product filling quantity) |

| Machine weight | 800KG | 800KG | 900KG | 1000KG |

| Total Power | 2.0KW | 2.0KW | 2.0KW | 2.0KW |

| Work Flow | 1. Giving bag, 2. Pick up the bag (coding), 3. Open the bag up and down, 4. Filling, 5. Heating sealing, 6. Output of the product | |||

| Dimensions | 1750 × 1285 × 1360mm (L×W×H) | 2140 × 1366 × 1360mm (L×W×H) | 2140 × 1366 × 1360mm (L×W×H) | |

| Collocation | Screw metering, screw elevator | |||

| Product Name | Automatic Powder Filling Production Line |

| Model | LD-PAF01 |

| Filling Range | 10-5000g (Customizable) |

| Filling Speed | 20-40 bottles/min |

| Measurement Accuracy | ±1% |

| Power | 5 KW |

| Working Power Supply | 220V, 50Hz |

| Working Pressure | 0.6-0.8MPa |

| Weight | 550kg |

| Size | 2006 × 979 × 2068mm (L×W×H) |

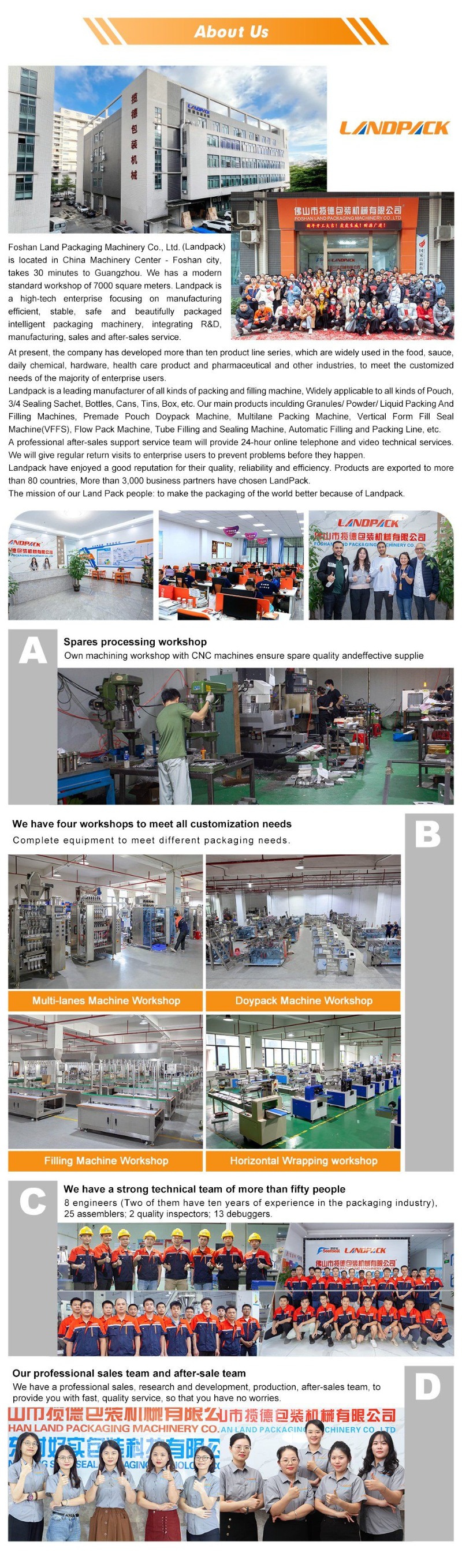

Pre-sale Service

1. Equipment model selection;2. According to the special requirements of customers, personalized customized products;

3. Train technicians for customers free of charge;

4. Free professional technical engineers to plan the site on-site and design the best process and plan.

5. Acceptance of the product;

6. Assist the client in drafting the construction plan;

Medium-sales Services:

Landpack has a trained team to follow your orders methodically to guarantee the products can be finished

on time with high quality.

After-sales Service

1. One-Year Warranty, As long as there is a non-human fault in a year, free replacement parts.

2. Parts Replacement, Don't worry about the parts damaged or not sold after the machine is sold. we have a field factory with hundreds of employees to serve you.

3. Engineer Assignment, Lifelong maintenance, if your equipment breaks down, we will arrange for engineers to repair it.

4. Online Instruction, We open online services, as long as your equipment fails, our engineers will be the first time for

one-to-one troubleshooting.

5. Feedback Survey, the engineer is required to bring a questionnaire to fill in the satisfaction with the engineer and the use of the equipment.

When the machines are finished:

2. We also provide the test report of the machine. Before the machine leaves our factory, we need to receive the balance.

3. The machines would be wrapped by a waterproof membrane and packed in a wooden box.

4. Our long-term cooperative shipping company to send the machine to your country in time.

Contact us

Company Address:

Building C7, New Lighting Source Industrial Base, Nanhai District, Foshan, China

If You Would Like To Visit Our Just Now, Please Contact Us and We Will Arrange a Special Bus To Pick You Up.

Kindly Reminder:

Please let us know the following packing details when you offer so that we can check if this model is suitable for your case. Thank you in advance.

1. Product details

2. Bag width, bag length

3. Bag shape

4. Packing film material

5. Machine frame

LANDPACK MACHINERY is still developing, and the products are also being innovated. Welcome our old and new customers to visit our factory and make a consultation.

We will provide professional packaging solutions for you!

A: Dear, before quoting, please kindly consult us and providing:

1. Your product name, and product picture.

2. Your bag size, such as bag width and bag height.

3. Ideal bag shape. For there are over 100 kinds of packing machines, different in bag size.

In order to recommend u the best, we need to know that information.

If u just start this business, no bag size, we can help u to find similar-weight bags for your reference.

2. Q: Is that packing machine ok for our product? How to operate it?

A: If you don't mind, you can send u a sample. We will use the existing packing machine to test for u.

During that time, we will take a video and a clearer picture for you. If chance, we can take a video online and show u.

3. Q: Is that pack many bag sizes in the same packing machine?

A: That is the common question from our customers. Every packing machine has its range for bag length and bag width. Can u send us full details, I will calculate for u and give u an exact reply.

Need more machine details or videos? Please contact us directly!