Full Automatic Metal/ Aluminum Tube Filling Sealing Machine

- One Year Warranty

- User Manual

- One-to-one Video Chat Support

- Install & Debug Video

- Custom Package Solution

Full Automatic Metal/ Aluminum Tube Filling Sealing Machine

Application

Ideal for packaging liquid and paste products including:

-

Cosmetics: hand cream, facial lotion, shampoo, gel

-

Personal care & Hygiene: toothpaste, antimicrobial creams

-

Industrial & Chemical: adhesives, epoxy resins, glues, lubricants

-

Pharmaceutical & Medical: ointments, gels (e.g., AB glue, epoxy glue)

-

Other Viscous Materials: shoe polish, leather care, silicone sealant

Filling container: Plastic tube; Composite tube;Aluminum Tube

Optional Supporting Devices: three-dimensional packaging machine, cartoning machine, sealing machine, heat shrinkable machine, etc

-

Dual‑Format Compatibility: Supports both plastic and metal/aluminum tubes (diameter Φ15‑70 mm, length 50‑180 mm)

-

High Precision Filling: ±1% accuracy with adjustable volume (40‑60 ml)

-

Fast Production Speed: Up to 43,600 pcs/hour (adjustable), ideal for high-volume lines

-

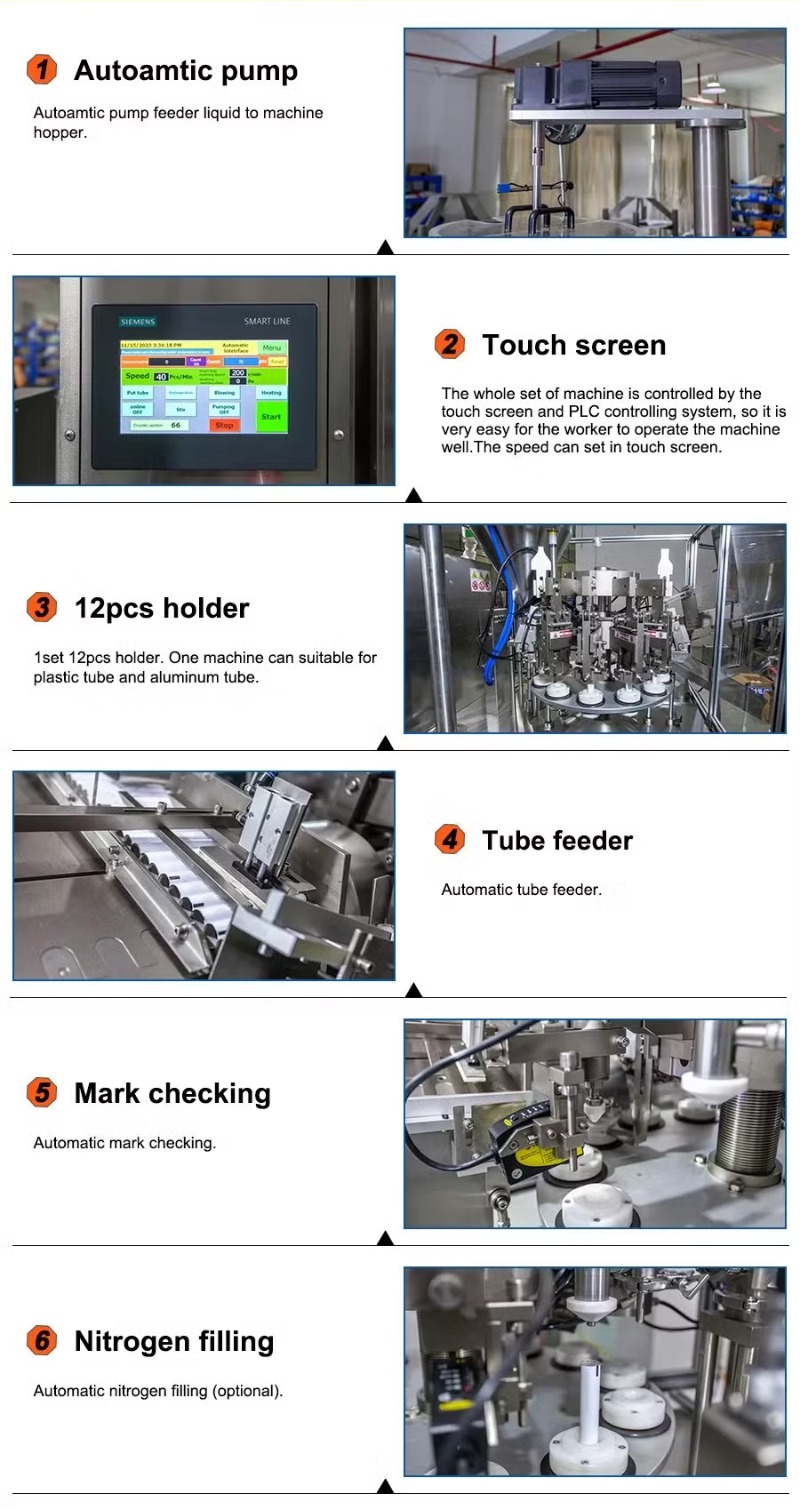

User‑Friendly Control: PLC + touchscreen for easy setup and parameter control

-

Quick Changeovers: Tube type swap can be done in minutes

-

Robust Construction: Full stainless steel (316L) product contact parts, aluminum alloy frame – meets GMP standards

-

Multi‑Station Process: Auto tube feeding, nitrogen purging, filling, heating/sealing, folding, crimping, and batch coding

-

Automated Safety: Photoelectric detection, overload protection, and automatic shutdown on door open

-

Customizable Design: Adjustable tube seals, nitrogen purging option, clean-room compatible

Working Flow:

1. Tube feeder

2. Mark checking

3. Nitrogen filling (non-standard matching)

4. Filling

5. Plastic tube heating

6. Plastic tube sealing station/production batch number station

7. Aluminum tube clamping and flattening station

8. Aluminum tube first folding station

9.Aluminum tube second folding station

10.Aluminum tube stamping/production batch number station

11.Plastic tube Trim and cut waste edges

12.Finished product take out

| Model | LFF-ZW-08 | |||

| Tube material | Aluminum / Metal tube | |||

| Tube diameter | φ15–φ70 | |||

| Tube length | 60–280 (customizable) | |||

| Filling volume | 10–480 ml/pcs (adjustable) | |||

| Filling accuracy | ≤ ±1 % | |||

| Product capacity | 1800–4000 pcs/h (adjustable) | |||

| Working pressure | 0.55–0.65 MPa | |||

| Motor power | 2 KW (380 V/220 V 50–60 Hz, three phase) | |||

| Working Position | 10 Automatic Aluminum Tube Filling And Sealing Machine with Cover Pcs | |||

The Machine Details of Full Automatic Metal/ Aluminum Tube Filling Sealing Machine