Automatic Double Head Powder Tin Can Filling Machine Line

- One Year Warranty

- User Manual

- One-to-one Video Chat Support

- Install & Debug Video

- Custom Package Solution

Automatic Double Head Powder Tin Can Filling Machine Line

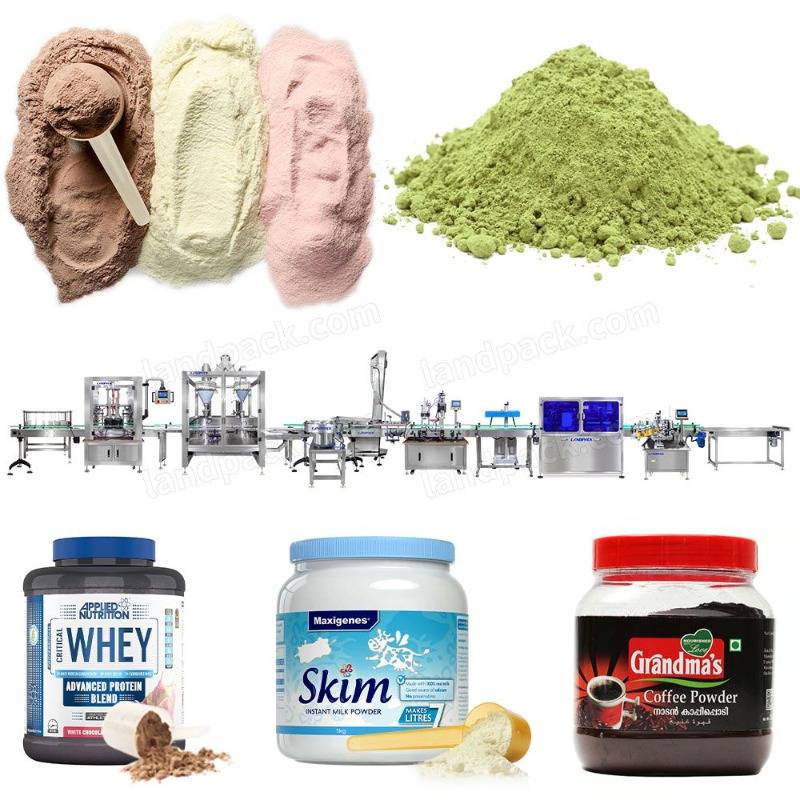

The Application of Automatic Double Head Powder Tin Can Filling Machine Line

Application:

This powder filling line is suitable for protein powder, milk powder, health powder, medical powder, nutrition powder, monosodium glutamate, solid beverage, icing sugar, dextrose, feed, coffee, solid medicament, etc.

Packaging Type: Cans, Tins, Barrel, Bottles, Capsule, Cartons, Stand-up Pouch

Packaging Material: Glass, Metal, Paper, Plastic, Wood, Other.

Kindly Reminder:

We have an experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Samples

The Features of Automatic Double Head Powder Tin Can Filling Machine Line

1.Full Frame SS304 easy Clean.

2.Air Blow Ion cleaning for dusty remove from the empty bottle no need dry machine.

3.Double Head Filler: Main Filling and refilling to confirm high precision filling.

4.Servo motor and servo controls the auger measuring.

5.Dusty Proof Filling nozzle function to keep easy clean.

6.Built in Weighing filling function and also the check weigher function keep filling accuracy.

7.Eliminated function, if the container less grams or over grams will be delivery on the other collection conveyor side.

8.Panasonic PLC+Weiwview touch screen easy to operate.

9.Linear Type conveyor higher speed.

10.Dusty collection device.

11.Spoon feeder with vibration to feed the spoon into the big container easy to drop design.

12.Pressing Spoon Device to keep Spoon inside of the container easy for the capping part.

12.200L Cap Lifter for feeding the cap easier and faster sensor for the cap no lids no capping.

13.Servo Motor controlled Capping machine with press capping system make the capping more tightly.

14.Foil sealing machine to keep the powder not easy to be wet and prevent air go into container and keep the fresh of the powder.

15.Can body cleaning machine with brush rollers and wind knives, can be cleaned by sweeping blowing and sucking in all direction.

16.Round bottle labeling machine can suitable for the small and bigger round bottle labeling customized for end customer.

17.With Ribbon date printer can printed the batch Number, Lot. EXp max 3 lines on the stick labels easy to tracking the production.

18.Finished powder bottle collection table for manual work efficiency.

19.All Line conveyor belt is customized 200mm suitable for small and big bottles go through all the line.

Work Flow:

1.Belt Bottle Feeder.

2.Double Head Air Blow Ion Cleaning Machine.

3.Auger Feeder.

4.Double Head Weighing Filling Machine.

5.Spoon Feeder.

6.Press Spoon Device.

7.Cap Lifter for feeding the cap.

8.Servo Capping Machine.

9.Foil Sealing Machine.

10.Bottle Cleaning Machine.

11.Round Bottle Labeling Machine.

12.Finished Bottle Collector.

The Description of Automatic Double Head Powder Tin Can Filling Machine Line

|

Product Name

|

Automatic Double Head Powder Tin Can Filling Machine Line |

|

Model

|

LD-PAF01

|

|

Filling Range

|

100-2000g (Customizable)

|

|

Filling Speed

|

10-25 bottle/min

|

|

Measurement accuracy

|

±1%

|

|

Power

|

4.5 KW

|

|

Working power supply

|

220V,50Hz

|

|

Working pressure

|

0.6-0.8MPa

|

|

Weight

|

500kg

|

|

Size

|

L11782*W3465.09*H2523.52(mm)

|